Tagged: Welding

STATCOM Case Study

STATCOM AHF Reduces Flicker

Due to an increased usage of the local grid, a stricter limit of flicker emission became a necessity. One of the largest steel wire producers in Europe managed the problem by installing a STATCOM solution and lowering their flicker emissions.

Background

The processing plant is the largest steel wire producer in Europe, part of a German industry group founded in 1856. The company produces steel reinforcement mesh grids. The production line is made up of various welding equipment, including spot welders from Schlatter AG. As is the case with all powerful spot welders, the abrupt current consumption causes voltage variations, which in turn produces flicker.

Challenge

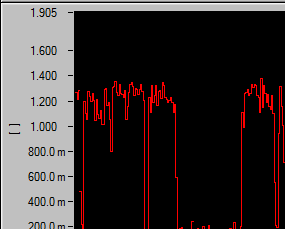

Due to expansion of the area and increased amount of renewable energy sources, it became necessary to lower flicker contribution. Early reference measurements showed flicker levels up to Pst 2 and Plt 1.4. A futher

complication the the case was caused by a lot of switching activity in the surrounding electrical grid. This contributed to higher background flicker and making measurements more difficult. Finally, depending on the production type currently running, the flicker will vary.

STATCOM by AHF – the Solution

The solution was offered in cooperation with Schlatter AG, who also delivered the welding lines.

A STATCOM solution consisting of 7 300/690W water cooled active harmonic filters was installed. The nominal installed power is 2.5 MVAr. The fully water cooled STATCOM follows the load dynamically. Neither changes in the production nor newly installed equipment leads to any need for adjustment of the compensation system. The AHF units were installed via a dedicated transformer and use their own medium voltage measurement point.

Delivered Results

The STATCOM solution reduced the flicker level to Plt 0.6. Reduced reactive power lowered current consumption 25-40%. Voltage dips on the 20 kV rail were lowered from around 500V to around 100V.

Flicker Compensation Case Study

AHF Reduces Flicker from Radiator Production

Today’s industry constantly faces new challenges. As the local community grows, large businesses with energy intensive production processes are faced with the challenge of reducing their effects on the grid. High flicker emission levels can potentially disturb other industries on the public grid.

Background

The plant is a 55000 square meter radiator factory in Belgium, It consists of six production lines that in total can produce about 5000 radiators a day. The production process consists of presses, seam welding and spot welding. The process is inherently very energy demanding and so puts great demands on the power grid. These processes combined to create large voltage drops in the feeding substation with the result of too high Pst values. The problems at the plant caused flashing lights when the local utility company would connect other consumers to the same transformer.

Challenge

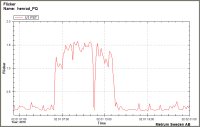

The local utility company demanded that the Pst 95% value could not exceed 0,7. Measured values during 2009 showed tops in the Pst equivalent to 1,6. Achieving this goal was no small feat due to the rapidly fluctuating load, and the many different load patterns that could occur with such a high number of welding machines.

Active Harmonic Filters – the Solution

The market leading response time for the active harmonic filter was a necessity for the customer to reach the values that the utility company demanded. The system consists of six units, making it a total of 2,1 MVAr continous power to compensate for the voltage drops.

Installation of Active Harmonic Filters Creates Results

After installing the active harmonic filters, the plant has managed to keep their Pst value below 0,63, regardless of how many welding lines are run simultaneously. The reference values have been measured by external consultants and approved by the local utility. As a side effect of the lowered flicker value, the plant now also enjoys stabilized production environment.