Category: Active Harmonic Filters

Active Harmonic Filters – Buyer’s Guide

Active Harmonic Filters are growing in popularity as a method to mitigate power quality issues. There are several factors to consider when specifying an active harmonic filter. Typical applications for active filters are compensation of variable frequency drives and data-centers to reduce the load on UPS systems or compensating the effects of renewable energy sources on the grid.

What is an Active Harmonic Filter and what is its Application.

The general definition to describe this application is an analog or digital device that measures the power quality on the grid side. It then injects current to compensate any unwanted deviations from the standard 50 or 60 Hz supply. Deviations can be mitigated in full or partially.

What Factors to Consider when Specifying an Active Harmonic Filter

Sensor or sensorless control

There are suppliers that provide sensorless control eliminating the need for current transformers. This solution reduce the installation cost. Sensorless is not used in all applications so make sure to check the application with the supplier. Sensorless control or voltage control as it is sometimes defined compensates the total THD. It is not possible to select a single source such as a single VFD. On the plus-side it is possible to protect a sensitive subgrid from a noisy primary grid.

Losses

Depending on design, the filter has higher or lower losses. Check the losses as this will reduce the Life Cycle Cost on your investment. Some active filters have up to 1%-point lower losses, which depending on your user profile, means a potential for considerable financial savings if calculated LCC over 5 years.

Harmonic Compensation Capacity

Harmonics are normally seen in the odd. Common capacity for active filters is 25th or 50th harmonic. Sometimes there is a claim of being able to mitigate the 51st harmonic, which has little value as harmonic order of 51 and above are normally not important.

Harmonics above the 50th are more difficult to measure as there are few PQ-meters that can handle such orders. There are however quite common sources such as Active Front End Drives that cause switching ripple above 3kHz, above the 60th harmonic (or above the 50th in 60 Hz systems).

There are a few Active Harmonic Filters capable of compensating such frequencies. Choose a filter according to the needs specified by your measurements.

A filter’s capacity to compensate a certain harmonic order is only part of the story. Another important factor is de-rating, discussed below.

Response time

Some power quality phenomena occur extremely fast requiring the mitigation to be even faster. If your process is affected by fast flicker or transients, take special care to evaluate the response capacity of the filter. Flicker is a specific phenomena that normally requires special software to compensate flicker in a controlled environment.

Interharmonics

Interharmonics is commonly caused by syncronisation issues. If your installation includes such interharmonic sources, the type of active filter changes and the vendor has to be consulted. This is a common issue on some types of older wind turbines.

EMC

In Europe there are strict guidelines regarding EMC. If you want to be sure that the active filter does not interfere, the filter must be fitted with a properly tuned EMC-filter.

De-rating

An Active Harmonic Filter’s rating is normally defined at nominal load, meaning at 50/60Hz. As the filter works further up the harmonics its capacity compared to nominal starts to de-rate. The de-rating curve is documented by all serious suppliers and should be available if you ask them.

A de-rating of 50%, at say the 13th harmonic, means that a 100A filter only has the capacity to compensate 50A at the 13th. Naturally if you have harmonics of higher order it becomes more important to check the de-rating.

De-rating is a matter of how robustly the filter is designed. Some suppliers offer zero de-rating up to the 7th before capacity starts to fall.

Physical Footprint – How Much Cabinet Space is Required?

Most active filter suppliers offer several alternatives regarding installation. Wall mount, Cabinet and IP00 modules to install in cabinets. Efficient use of cabinet space translates to lower system cost. Some filters have a modular design and can be enhanced with further capacity without adding to the footprint.

Modularity

As mentioned, a modular design of your Active Harmonic Filter enables you to adapt the filter to potential changes in your future power compensation needs. The modular design means that you can easily add to the filter’s capacity within the existing cabinet, saving both cost and space.

Commissioning Software

Does the filter have built in commissioning software? Commissioning and service of Active Filters can be quite time consuming. Ask for a review of the support software included in the machine. Some suppliers have an extra charge for the necessary software. Minimum required functionality should be that the system performs a self-check of Voltage and CT phase order, CT polarity check, self-diagnosis, and self-calibration. Such features will quickly find installation errors before they can cause problems and will also shorten the needed commissioning time.

If the filter does not have this type of support software the commissioning becomes much more complex and might even require external support adding to the system cost.

HMI

There are different HMI setups. Some have a very simple front HMI while others include graphs showing the current and voltage waveforms and many further functions. A great added value is to have at least a web-based interface allowing in-depth monitoring and control functionality. Then no extra PQ-meter is necessary.

Smart Grid Functionality

Active filters have a built in rudimentary power and power quality meter to calculate the required compensation. Some filter manufacturers make use of this fact and enable the user to connect all filters on site and company wide through a web based architecture. An operator can then have an overview of the status of all connected cabinets and log them. This enables the possibility to log events that could or should have caused production disturbances, status monitoring of individual filters as well as remote control capability. Email and text alerts to dedicated service personnel from the filter reduce response time dramatically.

IP/NEMA Class and Water Cooling

Water-cooled Active Filters enable very good cooling of the IGBTs, the most critical component in the Active Filter. Water-cooling reduces overheating immensely, which increases availability in the same way as for Variable Frequency Drives. The power density of the installation is also improved.

Voltage

Active Harmonic Filters are offered in a range of voltages. Most common ranges are 380–415V, up to 480 V. Higher voltages up to 600 and 690V are also available without step-up transformer, reducing foot print. Some suppliers have the capacity to supply MV ratings as well, normally using a step-up transformer. The active filter can then act as STATCOM.

Battery add-on

In recent years several suppliers are offering battery connectivity to create a battery energy storage system for FCR and peak shaving. The active filters on-load capabilities are perfect for grid connectivity applications.

Sensorless Voltage Control

Recently a new type of sensorless solution make it much easier to install as no CTs are required which is standard for active harmonic filters. This method can not control specific frequencies but can be used to even mitigate noise from the grid.

Resonance Damping

Some filters offer resonance damping making them ideal in highly complex situations.

Multimaster

When building large systems with several filters acting together they are normally controlled by a master filter. In these cases some suppliers provide a multimaster option. In case the master-filter fail, another filter take up the master role and the system as a whole can continue filtering.

Power Losses and Low Harmonic Drives

Using the active filter in shunt applications has a lot of energy saving potential compared to using serial filters – either passive or active front end.

Here are some examples and what they mean to you as user. When seen as a system, the active filter in shunt mode offers a total system loss that is lower than that of the passive filter.

Passive Harmonic Filters

A passive filter has between 0.6-1.5% losses

Assuming a 6-pulse drive has 2% losses, the total system loss is the sum of the losses

Pdrive*PFilter = 2% + (1.5 <-> 0.6)% => 3.5% to 2.6% total system loss.

NOTE! This does not include an eventual voltage drop through the passive filter and its effect on the motor’s losses.

Serial Active Filter – Active Front End

An active front end drive essentially has twice the loss of a standard drive as the power has to pass through two IGBTs.

Pafe = 2% + 2% + 1% for the LCL-filter = 5% losses. Total system losses observed in documentation are 4.7-5%.

Shunt Active Filter – Commonly named Active Harmonic Filter

Unlike the serial solutions the shunt active filter only has to be sized according to the harmonic currents to be filtered out. Under normal conditions this means that in a IEEE-519 or G5/4 application the filter has to be sized 15-30% of the 6-pulse load. This means the total system loss is also much lower even though the efficiency of the Active Filter is:

Pdrive + Padf = 0.02 + 0.02* (0,15 – 0,3) = 2.3 – 2.6 % in total system losses.

Summary from a System Owner’s View

Shunt Active Harmonic filters offer between 0 and 1.17% points lower power consumption compared to Passive Harmonic Filters. This does not include any effect from voltage drop through the serial passive filter.

Shunt Active Harmonic Filters offer between 2.7 – 2.4 % lower power consumption compared to Active Front End drives.

Power Losses are a Significant Part of Your Life Cycle Cost Calculation

Minimising losses over time, especially in industrial process loads with more than 8000 hours of yearly operation, 1%-point saving in power consumption translates into significant value.

(Pdrive + Pcooling) (kW)* Yearly operation hours(h)*Net Losses(%) = Total cost saving potential

Energy Cost Estimate

Electrical power prices differ but the relation between cooling and electricity is roughly equivalent to

Pcooling = 0.3 * Pdrive

In the case of the AFE there are cases where the entire harmonic mitigation solution has been paid off in 2.5 years simply by choosing shunt Active Harmonic Filters instead of Active Front End thanks to lower power losses.

The Active Harmonic Filter is very competitive compared to both Passive filters and Active Front End. As the capital expenditure is very similar, a lower power consumption make the AHF a very good overall choice.

Furthermore the availability offered by a shunt installation where the drive can continue to operate even though the mitigation has failed offer a great upside through higher availability of the process.

Applications of Active Filter Technology

Active Harmonic Filter Technology have many potential applications where its use can offer plenty of benefits. Active Filters have been proven to provide lowered disturbances, lower carbon dioxide emissions through improved energy efficiency, lower current consumption and increased production stability to name a few. Just as other technology has evolved, so have various production technologies. Today’s semiconductor loads require far more sophisticated solutions than was necessary in the past – a need met by modern Active Filtering technology.

Some of the most common applications for Active Harmonic Filters are:

Variable Speed Drives

The most common application for Active Filters is the compensation of harmonics generated by variable speed drives, often referred to as VFDs or Frequency Converters. Drive systems have the benefits of lower losses and increased production flexibility at the cost of higher harmonics emissions. Harmonics emissions make passive compensation unsuitable. Active harmonic filtering, especially with a modular approach, allows successive installation and mitigation of selected harmonics.

Welding Plants

Electrical welding systems place uneven demands with extremely high peaks in current demand during short periods. The resulting highly fluctuating voltage levels cause flicker. Flicker emissions can cause disturbances with other electrical consumers such as neighboring industries or residential areas and can cause reliability issues with nearby equipment. Active Filters can mitigate Flicker.

Furnaces

Furnaces and casting processes are known to give rise to both flicker and harmonics. This is largely due to being some of the most energy intensive production processes today. Active Filtering technology is ideal to combat both of these issues to increase production stability and reduce effects on the grid.

Wind and Solar Power Systems

A major problem inherent in many renewable energy sources today is the inconstant load delivered to the grid. Both wind and solar energy is delivered as wind and sun is available, causing surges of energy that the existing grid is usually not built for. The remote location of these energy plants also means that grid connections are suboptimal.

Wind power systems cause flicker, harmonics or interharmonics as well as other problems. Solar power plants cause harmonics and interharmonics. In some cases, especially in weaker networks, resonances may be excited by the harmonic output of the solar inverters. Modern Active Filtering technology is very effective in combatting these problems; reducing the stress placed on the grid and making these renewable energy sources more effective and widely viable.

Lighting

Light systems can cause harmonics that heat neutral conductors and disturb nearby equipment. This can mean production disturbances and unnecessary maintenance costs. Modern energy saving lamps may be more likely to cause disturbances depending on type. Active Filters are well suited to combat these problems.

UPS Systems

UPS or Uniterruptible Power Suplies can save lives as well as data and financial loss. A UPS system connected to a network polluted with harmonics can malfunction and has a shortened life span. Connecting an Active Filter to secure uninterrupted power supply will ensure production uptime.

Active Harmonic Filters In Printing Applications

Harmonic Filter Restores Power Quality and Reduces Downtime Caused by Harmonics

Problems with power quality often become apparent through problems in production and surrounding equipment such as lighting.

This is what happened at one of the largest printers in Holland.

Background

The printing company consists of two printing plants located in Amsterdam. The plant employs 170 people, producing six daily newspapers and several other free local papers and magazines. The plant prints up to 1 million papers every day with printing presses running almost nonstop.

Poor Power Quality – the Challenge

The printers had been struggling with power quality problems for many years. Flourescent lighting had to be changed continuously as the tubes kept failing. The electrical ballast had to be changed every six months instead of every 5 years. This kept one employee busy 2-3 days a week. In 2011 just the lighting problems and other broken components cost the printers about

300 000 €. In addition to these losses, the plant had power quality related problems during startup of the presses, which resulted in additional losses through production downtime.

Active Harmonic Filters – the Solution

The printing group decided on an investment in power quality and quite literally, a brighter future. Six harmonic filters with a total compensation current of 1800 A were installed to optimize the power grid and reduce harmonics.

Harmonic Filtering Gave Quick Results

Following installation and commisioning of the active harmonic filters all previous problems disappeared. The printing plant can nowuse their printing presses without disturbances from poor power quality. Due to the continuous stops in production and equipment failure, which had been a daily occurrance, the return on investment for the harmonic filtering system was very short.

Harmonics and Notches in Dynamic Test Load

Active Harmonic Filters Improve Dynamic Test-Bed

A major pioneer in the manufacturing industry caused problems on the power supply network with their dynamic test bed. Here, an installation of the right combination of active harmonic filters now compensates harmonics up to the 100th order with great results. Both harmonics and voltage notches are reduced to enable top performance of the equipment.

Case Background

The test benches, owned by the development department of a major European production plant, are used to test components in the development phase. Varying test conditions can be programmed, which gives the test bench very dynamic properties.

Harmonics Compensation Challenge

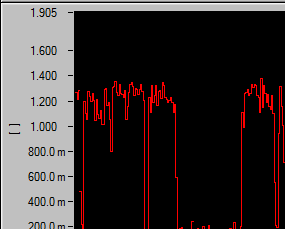

The same transformer is connected to two parts of the test bench. With a very dynamic load whose load current amplitude can change from zero to maximum in approximately 100 ms, it was impossible to run both parts of the test bench simultaneously. The voltage notches of up to 25% in combination with very high harmonic disturbances prevented this. This caused serious delay in the testing facility as well as exceeding the limits in EN61000-2-4.

Active Harmonic Filters – the Solution

To solve the power quality issues, several active harmonic filters were installed to compensate the disturbances. Two 200/480V filters were installed together with one 100/480V filter that in combination compensate all frequencies up to the 100th harmonic order. The first two filters can be used to compensate lower harmonics while the third compensates for higher order harmonics and interharmonics. The three units were configured to share the

load with the 100/480V filter working on higher orders only. This resulted in extremely short response times and considerably lowered load disturbances.

Harmonics Compensation – the Result

Thanks to the active harmonic filter installation, voltage notches could be reduced to 10%. In addition, harmonics were lowered to the required level stipulated in EN61000-2-4. Now, both test benches can be run simultaneously without any of the problems caused by poor power quality.

STATCOM Case Study

STATCOM AHF Reduces Flicker

Due to an increased usage of the local grid, a stricter limit of flicker emission became a necessity. One of the largest steel wire producers in Europe managed the problem by installing a STATCOM solution and lowering their flicker emissions.

Background

The processing plant is the largest steel wire producer in Europe, part of a German industry group founded in 1856. The company produces steel reinforcement mesh grids. The production line is made up of various welding equipment, including spot welders from Schlatter AG. As is the case with all powerful spot welders, the abrupt current consumption causes voltage variations, which in turn produces flicker.

Challenge

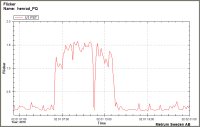

Due to expansion of the area and increased amount of renewable energy sources, it became necessary to lower flicker contribution. Early reference measurements showed flicker levels up to Pst 2 and Plt 1.4. A futher

complication the the case was caused by a lot of switching activity in the surrounding electrical grid. This contributed to higher background flicker and making measurements more difficult. Finally, depending on the production type currently running, the flicker will vary.

STATCOM by AHF – the Solution

The solution was offered in cooperation with Schlatter AG, who also delivered the welding lines.

A STATCOM solution consisting of 7 300/690W water cooled active harmonic filters was installed. The nominal installed power is 2.5 MVAr. The fully water cooled STATCOM follows the load dynamically. Neither changes in the production nor newly installed equipment leads to any need for adjustment of the compensation system. The AHF units were installed via a dedicated transformer and use their own medium voltage measurement point.

Delivered Results

The STATCOM solution reduced the flicker level to Plt 0.6. Reduced reactive power lowered current consumption 25-40%. Voltage dips on the 20 kV rail were lowered from around 500V to around 100V.

Flicker Compensation Case Study

AHF Reduces Flicker from Radiator Production

Today’s industry constantly faces new challenges. As the local community grows, large businesses with energy intensive production processes are faced with the challenge of reducing their effects on the grid. High flicker emission levels can potentially disturb other industries on the public grid.

Background

The plant is a 55000 square meter radiator factory in Belgium, It consists of six production lines that in total can produce about 5000 radiators a day. The production process consists of presses, seam welding and spot welding. The process is inherently very energy demanding and so puts great demands on the power grid. These processes combined to create large voltage drops in the feeding substation with the result of too high Pst values. The problems at the plant caused flashing lights when the local utility company would connect other consumers to the same transformer.

Challenge

The local utility company demanded that the Pst 95% value could not exceed 0,7. Measured values during 2009 showed tops in the Pst equivalent to 1,6. Achieving this goal was no small feat due to the rapidly fluctuating load, and the many different load patterns that could occur with such a high number of welding machines.

Active Harmonic Filters – the Solution

The market leading response time for the active harmonic filter was a necessity for the customer to reach the values that the utility company demanded. The system consists of six units, making it a total of 2,1 MVAr continous power to compensate for the voltage drops.

Installation of Active Harmonic Filters Creates Results

After installing the active harmonic filters, the plant has managed to keep their Pst value below 0,63, regardless of how many welding lines are run simultaneously. The reference values have been measured by external consultants and approved by the local utility. As a side effect of the lowered flicker value, the plant now also enjoys stabilized production environment.

Harmonics Mitigation on VFD – Case Study

Harmonics Mitigation Increases Output with 30%

The water treatment process involves a large number of variable-speed pumps to process large amounts of fluids. By using Active Harmonic Filtering technology to optimize the electrical behaviour of their variable frequency drives, a major water processing plant in Sweden managed to increase the maximum output capacity of their systems by 30%.

Thanks to Active Harmonic Filtering we can now process 30% more fluids during periods of peak demand. We also save energy.

– Project Manager

Background

The treatment plant is part of the sewage works in Gothenburg. It is one of the largest in all of Scandinavia and central to saving the environment from pollution. With heavy demands, the two basic requirements on this critical regional infrastructure are constant operation and sufficient treatment capacity. UPS power backup systems are crucial to ensure a secure and stable power supply.

To increase plant capacity, 17 new VFD-controlled pumps were installed at the processing plant. This increased harmonic distortion on the electrical system significantly and the resulting overcurrents caused the UPS fuses to melt. To avoid this, the pumps were run at reduced speed. This was however a temporary solution as it reduced treatment capacity below demand. Frequency converters are a well-known source of potentially damaging harmonics.

Harmonics Elimination – the Challenge

After consulting a premier Swedish consulting firm, the processing plant announced a public procurement process seeking the implementation of active harmonic elimination technology. The target was to retrieve full treatment capacity by eliminating the harmonics.

Solution – Active Filter Units

The result was the installation of two 600 kVA Active Harmonic Filter units to manage two transformers supplying 2160 kVA. There were a number of characteristics of the specific harmonic filter solution that led to the plant’s choice:

- Flexible connection and system dimensioning

- Reduced maintenance costs to other connected equipment

- Disturbance free electrical environment

- Reduced energy consumption through decreased transformer losses

Harmonics Eliminated – the Result

Eliminating the harmonics in the system resulted in an increased max output capacity of 30%.

In addition, the processing plant now manages to operate below the threshold value for harmonic distortion (SS 421 1811). The plant now enjoys further benefits with a reduced energy consumption and improved environmental performance.

Harmonics Case Study

Harmonics Case Study:

Secure Food Production by Mitigating Harmonics

Highly automized processes often contain VFDs, which cause harmonics in the power supply. This can affect machinery and can cause downtime in production lines. This was the case at a major food processing plant in Dortmund, Germany.

Background

The food processing plant is part of a federation of over 300 independent retail dealers and suppliers to approximately 540 grocery stores. The center is a 100.000 m² warehouse and distribution center with affiliated butcher. After the butcher was destroyed in a fire in 2009, it had been rebuilt and expanded in 2011 into an 18.000 m² large butcher shop. Since completion at the end of 2011, the new processing plant produces 250 tons of meat for the grocery stores and up to 25 tons of sausages every day. The new butcher shop contains state of the art logistics and meat processing systems.

Challenge

The VFDs connected to the new meat cutter created typical current harmonics of a six-pulse-converter (5th, 7th, 11th, 13th, etc). These harmonics resulted in commutation notches in the voltage, which influenced the whole production process. The harmonics caused blackouts and disturbances to the lighting. It also influenced the sausage stuffing and caused long production stops disturbing the process flow. Occasionally up to half of the employees had to be sent home for the day due to disturbances in the process.

Solution – Active Harmonic Filter with Harmonics Compensation

The food processing plant decided to use an Active Harmonic Filter to eliminate the problems in the power supply. The installed system consists of one filter with a capacity of 300 A harmonics compensation to provide the needed harmonic power for the meat cutter.

Result

After the installation and a short commissioning, all disturbing harmonics were cancelled and the commutation notches disappeared. All meat cutters could now, for the first time, be started at the same time, without any effect on lighting or the sausage stuffing process.

Trusted Suppliers

Trusted suppliers of Active Harmonic Filters

There are plenty of suppliers of Active Harmonic Filters on the market. Their capabilities vary and the innovations within the field have been numerous. While some filters really only compensate for harmonics, other Active Harmonic Filters have the ability to compensate for just about any power quality problems with a few software adjustments to fit your specific problem profile.

Investing in Active Harmonic Filters

Make sure to always start by getting proper measurements to ensure you know what issues are the real cause of your power quality problems. Harmonics is only one of many potential concerns with regards to power quality – transients, oscillations and flicker are just a few of the additional problems you could be facing.

There are many potential solutions within the power quality field. Keeping an open mind is the best way to ensure you get the most effective solution and best ROI on your investment. It may also be that a combination of technologies is the most effective way to protect your production.

Trusted Suppliers of Active Harmonic Filters

- Schaffner (www.schaffner.com)

- ABB (www.abb.com)

- Comsys (www.comsys.se)

- Danfoss (www.danfoss.com)

- Schneider (www.schneider.com)