Category: Uncategorized

Enabling a seamless Champions League final in Istanbul with Active Harmonic Filter

Service Partner: Wömner Power Quality Solutions

Location:Istanbul, Turkey

Industry: Sports Venue

Timeline: 2020-2023

Background

When Istanbul was selected to host the 2020 Champions League Final, the Turkish Football Federation contracted Renaissance Construction to renovate the city’s Olympic Stadium as the venue. Although the final was delayed until June of 2023 due to the pandemic, the work proceeded as scheduled and Wömner Power Quality Solutions, Comsys’s partner in Istanbul, was selected to ensure that no power quality issues would disrupt the prestigious event.

Challenge

Predicting what could go wrong during the final is difficult for various reasons. Firstly, power is peak during games, which take place only two or three times a month at most. Secondly, the stadium is supplied from several medium voltage (MV) substations, each having two backup transformers making the measurement of energy consumption complex due to the uncertainty of not knowing which of the three transformers is being utilized. Thirdly, a total of 25 km of MV underground cable creates 180 kVAR of capacitive power per hour. During game time reactive power is balanced, but on no load condition capacitive power is there and because it is on MV level it cannot be easily measured due to the position of the meter, which is 6 km away. And finally, two large scoreboards with a lot of power electronic equipment were installed for the final, creating harmonics.

The customer’s main priority was on harmonics and trips due to these, as well as on reactive power management. Normally, other power quality issues are quite small.

Solution

A total of seven Comsys ADF P100N active harmonic filters were installed by Wömner; two at each of the three main substations for the stadium, and one additional unit at a smaller utility substation.

Result

Since the filters were installed in early 2020, the customer has experienced no problems due to capacitive penalties and game nights have been safe and secure. The Active Harmonic Filter technology is successfully compensating harmonics and preventing capacitive penalties.

Merus Power case study on EV-charging station

Segment background

The battery-operated truck industry has emerged as a transformative force within the transportation sector, offering a sustainable and eco-friendly solution to the longstanding challenges of heavy-duty vehicle emissions and fossil fuel dependency. These electric trucks, powered by advanced lithium-ion battery technology, are gaining momentum as an integral component of modern urban logistics and long-haul transportation. With the promise of zero-emission operation and significant reductions in operating costs over the long term, battery-operated trucks are not only aligned with environmental objectives but also represent a strategic choice for businesses aiming to optimize their fleet operations, comply with tightening emissions regulations, and contribute to a cleaner and more sustainable future for the global transportation industry.

Challenges at the customer’s facility

Driven by the need to comply with stringent grid code requirements, our customer recognized the necessity of improving power quality at their electric vehicle (EV) charging station. Specifically, they were facing challenges with harmonics, a common issue arising from the use of both AC and DC charging systems. The AC chargers, converting AC power to DC for the vehicles, were causing harmonic distortions in the electrical grid. DC fast chargers further compounded these harmonic problems, even introducing voltage fluctuations. To rectify these issues and meet grid code compliance, solutions like harmonic filters and active power factor correction were essential. Effective management of these harmonics is not only critical for maintaining the stability of the customer’s EV charging station but also impacts the integrity of the surrounding electrical infrastructure.

Our Merus® Solution

To address the harmonic issues in our customer’s EV charging station, the recommended solution is the use of Merus® A2 Active Harmonic Filters. Suggested and installed by our local partner, Power Capacitors Ltd, the Merus® A2 offers an efficient way to improve power quality. These filters are specifically designed to manage the harmonics introduced by both AC and DC chargers, thereby enhancing the system’s overall performance and reliability.

Incorporating Merus® A2 into the electrical setup involves its strategic placement to effectively reduce harmonic distortions from the charging units. By actively isolating and filtering out specific harmonic frequencies, the Merus® A2 contributes to improved power quality, reduced voltage distortions, and a more stable electrical grid. The IP31 design of Merus® A2 ensured a seamless and straightforward installation, aligning well with the site’s indoor setting and existing infrastructure.

Segment / Application

EV-charging station for battery operated trucks

Location

United Kingdom

Power quality issue

- High current harmonic distortion

Merus® Solution

Merus® A2 – Active Harmonic Filter

Merus® A2 is a scalable, versatile, and durable active harmonic filtering solution designed and manufactured in Finland using innovative Merus® technology.

Customer Benefits

- Grid code compliance

- Reduced wear and tear on electrical components

- Reduced maintenance costs

- Longer lifetime of sensitive electrical equipment

- Improved system efficiency

- Optimized performance of the charging system

Results after installation

Since installing the Merus® A2 Active Harmonic Filters, our customer’s EV charging station has experienced significant improvements, including reduced wear on electrical components and extended equipment life. These improvements have resulted in a more efficient system that not only complies with demanding grid codes but also contributes to a more sustainable electric vehicle charging infrastructure. The expertise provided by our local partner, Power Capacitors Ltd., was invaluable in achieving these outcomes.

The Merus® A2 Filters have effectively minimized the harmonic distortions originating from AC and DC chargers. This optimization has led to increased energy efficiency and lower maintenance costs. Thanks to these advancements, the customer’s EV charging station now operates with improved power quality and grid stability, fulfilling industry standards for both performance and sustainability.

Case story: How AHF put a stop to packaging manufacturer’s production outages

Background

One of Canada’s largest manufacturers of innovative and sustainable packaging products was facing multiple transformer failures and production stops due to power quality issues at one of its many sites. The manufacturer needed to find a way to eliminate these recurring problems and troublesome interruptions. Multiple studies on power quality were performed by different contractors. Comsys Partner, ADM Engineering, was one of the companies performing power studies and providing analysis report.

Challenge

The challenge facing ADM was to determine what was causing the periodic failures in the main transformers and to recommend a reliable remedy. Following site measurements and subsequent analysis of the data captured by ADM and Comsys, the root of the problem was identified. The culprit was the resonance caused by the interaction between the natural resonant frequency of the power system, tuned capacitor banks, and nonlinear loads. Based on these findings, ADM was able to recommend ADF as the only viable solution to the site’s persisting problems.

Solution

ADF P300 – Active Harmonic Filters engineered and assembled by ADM using PPM300 modules.

Result

The ADF solution has been operating successfully since January 2020, eliminating resonance and harmonics as well as providing near unity power factor. Cost savings alone have amounted to around CAD 30,000 per month by eliminating harmonics and correcting the power factor. Increased uptime and productivity provide even more value.

Key Results:

- Mill power outage frequency significantly reduced

- Oil cooled transformer runs much cooler and requires less frequent oil changes

- Significantly reduced running temperature of several transformers

- Reduced nuisance trips and blown fuses of 600V switchgear

- Reduced saturation of feeding transformers, reduces voltage variations to nominal values

Current THD – before & after installing ADF

Power Factor – before & after installing ADF

Machine drives system supply voltages before active filters installation

Machine drives system supply voltages after active filters installation

Resonance damping using Active Harmonic Filter

LOCATION: Munich, Germany

INDUSTRY: Energy

TIMELINE: 2013

Background

SWM Services GmbH München is the public utilities company that supplies the city of Munich with electricity, natural gas, district heating and cooling, as well as fresh drinking water from the Bavarian Alpine foothills.

At one of their geothermal plants used for power generation and district heating, the use of a large number of frequency converters was creating major problems that only a solution from Comsys could solve. Fortunately for SWM, our partner in Bavaria, PQ ENGINEERING, was there to help

Challenge

At their Sauerlach geothermal plant in Munich, thirty six frequency converters on a single transformer are used for the cooling units. Due to the high capacitive components of the load, a resonance point is formed in the network at the 25th harmonic. The resonance is so extreme that it was causing not only unusual noises, but also massive violations of EN 61000-2-4 class 2 limits, along with warranty issues for the supplier of the electrical equipment.

Picture: Resonance without Active Dynamic Filter installed

Solution

After acceptance measurements carried out by PQ ENGINEERING revealed the limit value violations, a test installation with the active resonance damper Comsys ADF P200-100 was carried out. PQ ENGINEERING keeps these universal filters in stock for quick response to just such “emergencies”. Targeted programming of the filter’s impedance enabled the increased harmonics in the area of the resonance point to be reduced to a permissible level. After the test installation was completed, ADF P200 filters were installed on both of the main distributors. No other supplier was able to offer an active controlled solution for resonance damping.

ADF P200 (first generation) installed

ADF P200 (first generation) installed

Result

The solution completely dampened the resonance, thus eliminating the severe compliance issues.

Picture: Resonance after Active Dynamic Filter was installed

PERFECT RESONANCE DAMPING

• Highly dynamic damping of the resonance point

• Flexible use, even if the customer makes changes later

• Easy retrofitting in the fully assembled switchgear

Sneakpeek at Danfoss new Active Harmonic Filter

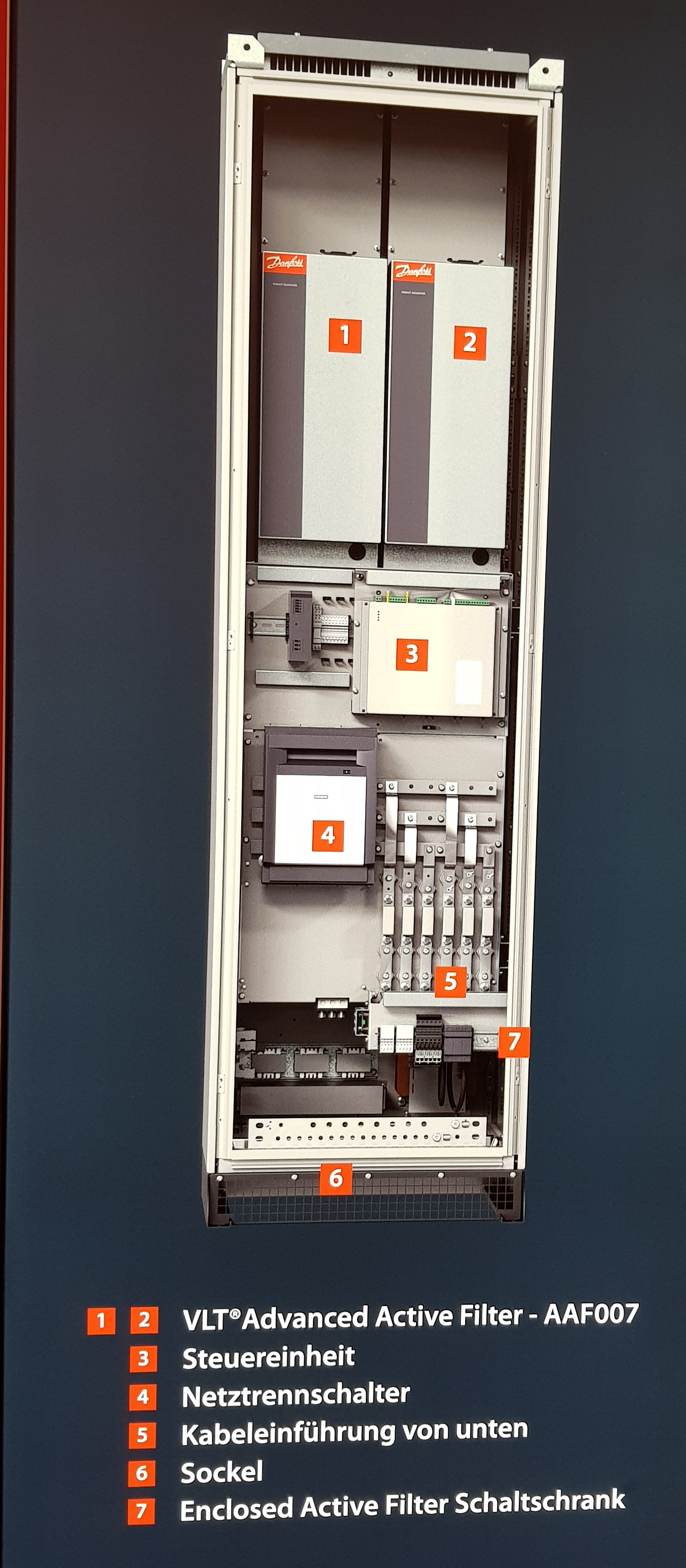

At the SPS fair in Nürnberg 2019, Danfoss gave a sneak peek its new active harmonic filter for high power quality applications. Sources say it is due to be launched in q1 of 2020. We look forward to check out its specifications. Danfoss was the first drives manufacturer to use active harmonic filters as a solution for their low harmonic drives, often applied when complying with for instance IEEE519. Last year Schneider followed up showing its Active Harmonic Filter in combination with multiple drives at SPS, see Active Harmonic Filters & Drives. The Danfoss filter AAF007 seems to be modular based on the picture presented.

Danfoss new Active Harmonic Filter AAF007

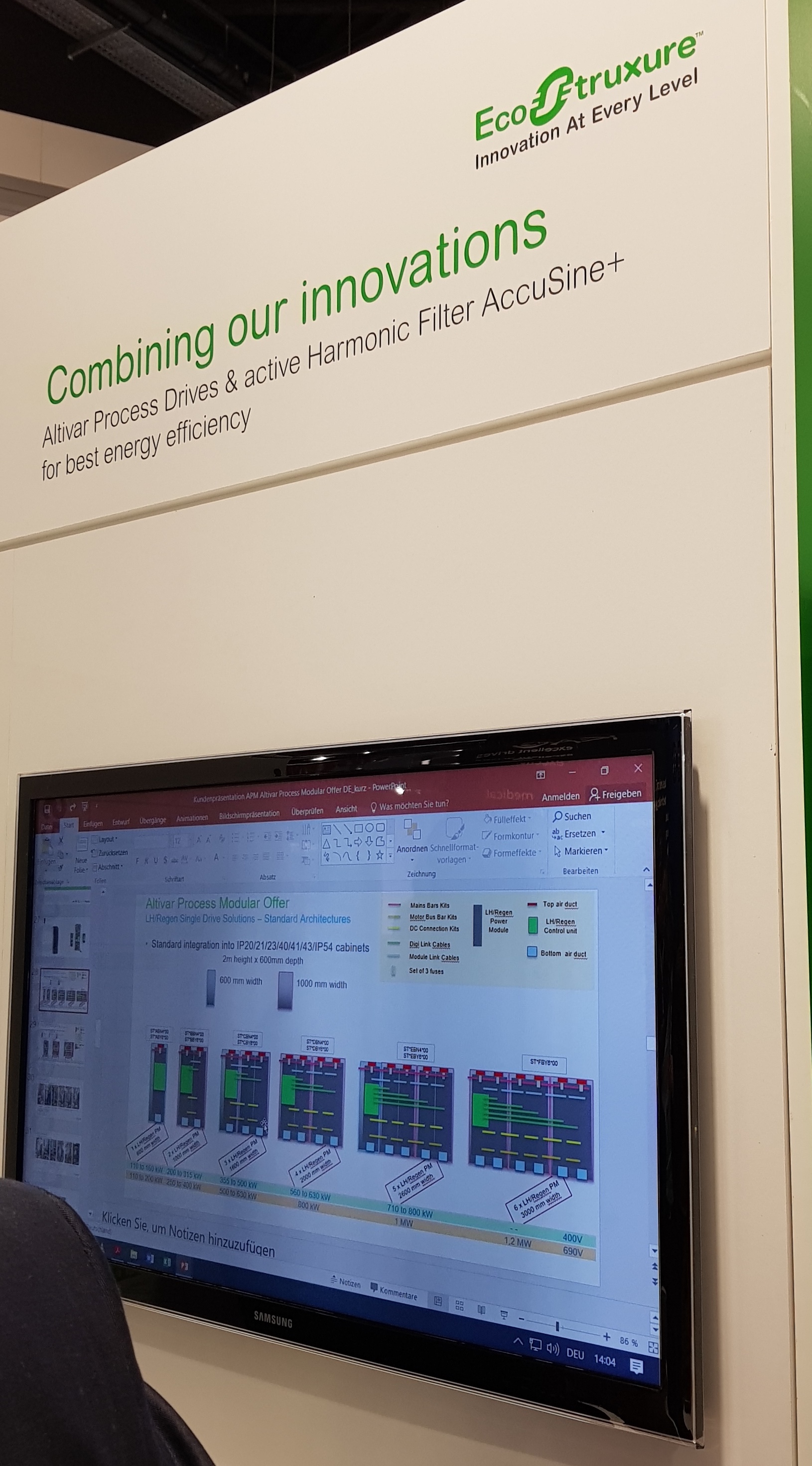

Active Harmonic Filters & Drives

If you have followed this site you know that for large drive applications the combination of VFD + AHF have several advantages over the serial solution AFE. By placing the Active Filter in parallel you obtain a more secure derive solution as well as higher efficiency. The losses in the Active Filter are about 25-30% of the losses in the Front End on a system-wide basis. The AFE has to pass the whole drive power through itself as it is placed in series with the load. The shunt mounted Active Filter however is sized based on the harmonic mitigation requirement, normally around 25-30% of total load.

Schneider showcasing the combination of Active Harmonic Filter & Drives for higher energyefficiency at the SPS2019 fair in Nuernberg.

For more on Active Filters and rives see the Global Active Filter Compensation post with an excellent paper on the advantages.

Small is the new black in the Active Harmonic Filter market

It is not only ABB and Schneider that release new, smaller Active Harmonic Filters. Comsys, a Swedish company specialized in Active Harmonic Filters presented their new ADF-P25 model at the SPS Nürnberg last November. We got a chat with Rickard Jacobson, Head of Sales and Marketing at Comsys.

“We see an increasing demand for smaller filters in applications such as datacenters and commercial buildings where harmonics is an increasing issue. We scaled down our current design to 30A but it offers all the functionality and robustness that you find in the larger industrialized versions. As this filters will be broadly utilizedused we have focused a lot on simplicity, plug and play, making it very easy to commission and operate. We offer the option of Sensorless control as well as WiFi to access a bigger user interface on a mobile device.

We think this can be a great entry offering as customers can test the solution without allocating too much funds. It fits well with larger HVAC systems and building technology in general.”

Small Active Harmonic Filters from Schneider

Schneider dedicated 3 meters of exhibition space to its active harmonic filters at the SPS fair in Nuernberg this year. Great to see that the big boys are catching on. Schneider is no newcomer to the field though, rather one of the biggest suppliers of active filters world wide. This is the first year they show these products at the SPS. This year small filters down to 20 A is a new offering from Schneider in the PCSn series. We assume this will broaden the application scope significantly.

Source: Schneider

For more info check out the PCSn flyer Schneider_PCSn_998-20306747_GMA

ABB launches new Active Filter

Active Harmonic Filters are moving into the mainstream. As the world embrace renewables, electrical vehicles etc the amount of inverters in the grid is growing. As the share of inverters grow, the stability of the entire power grid will be more vulnerable as the amount of turbine inertia is reduced. The last decade is already indicating a dramatic change in grid behaviour through the 24 hour cycle. Active grid stabilisation will become a need. Several suppliers of Active filters are adopting battery integration to provide a complete solution to offer active, reactive and harmonic mitigation in one box. Now ABB is launching a new series of products.

The new portfolio comprises five solutions: PQflexC – variable reactive power controller; PQdynaC – ultra-fast reactive power and unbalance controller; PQactiF – active harmonic filter; and PQStorI – battery storage inverter with power quality functions. Finally, PQoptiM controls and monitors power quality parameters. The product family is further enabled by ABB Ability™ to allow the devices to be operated and controlled via cloud-connected user platforms to enable real-time access of data. See more here.

We look forward to see more of the specs as they become available. Great to see ABB expanding their offering in this segment.

Global Active Filter Compensation

Comsys has released a application note explaining the detailed advantages of using central filtering of many drives rather than installing separate low harmonic drives. A central active harmonic filter is often the cheapest and most efficient answer to maintain code compliance.

Read the report here: Global-vs-Local-Compensation_Application_Note