Tagged: Harmonics

Enabling a seamless Champions League final in Istanbul with Active Harmonic Filter

Service Partner: Wömner Power Quality Solutions

Location:Istanbul, Turkey

Industry: Sports Venue

Timeline: 2020-2023

Background

When Istanbul was selected to host the 2020 Champions League Final, the Turkish Football Federation contracted Renaissance Construction to renovate the city’s Olympic Stadium as the venue. Although the final was delayed until June of 2023 due to the pandemic, the work proceeded as scheduled and Wömner Power Quality Solutions, Comsys’s partner in Istanbul, was selected to ensure that no power quality issues would disrupt the prestigious event.

Challenge

Predicting what could go wrong during the final is difficult for various reasons. Firstly, power is peak during games, which take place only two or three times a month at most. Secondly, the stadium is supplied from several medium voltage (MV) substations, each having two backup transformers making the measurement of energy consumption complex due to the uncertainty of not knowing which of the three transformers is being utilized. Thirdly, a total of 25 km of MV underground cable creates 180 kVAR of capacitive power per hour. During game time reactive power is balanced, but on no load condition capacitive power is there and because it is on MV level it cannot be easily measured due to the position of the meter, which is 6 km away. And finally, two large scoreboards with a lot of power electronic equipment were installed for the final, creating harmonics.

The customer’s main priority was on harmonics and trips due to these, as well as on reactive power management. Normally, other power quality issues are quite small.

Solution

A total of seven Comsys ADF P100N active harmonic filters were installed by Wömner; two at each of the three main substations for the stadium, and one additional unit at a smaller utility substation.

Result

Since the filters were installed in early 2020, the customer has experienced no problems due to capacitive penalties and game nights have been safe and secure. The Active Harmonic Filter technology is successfully compensating harmonics and preventing capacitive penalties.

Merus Power case study on EV-charging station

Segment background

The battery-operated truck industry has emerged as a transformative force within the transportation sector, offering a sustainable and eco-friendly solution to the longstanding challenges of heavy-duty vehicle emissions and fossil fuel dependency. These electric trucks, powered by advanced lithium-ion battery technology, are gaining momentum as an integral component of modern urban logistics and long-haul transportation. With the promise of zero-emission operation and significant reductions in operating costs over the long term, battery-operated trucks are not only aligned with environmental objectives but also represent a strategic choice for businesses aiming to optimize their fleet operations, comply with tightening emissions regulations, and contribute to a cleaner and more sustainable future for the global transportation industry.

Challenges at the customer’s facility

Driven by the need to comply with stringent grid code requirements, our customer recognized the necessity of improving power quality at their electric vehicle (EV) charging station. Specifically, they were facing challenges with harmonics, a common issue arising from the use of both AC and DC charging systems. The AC chargers, converting AC power to DC for the vehicles, were causing harmonic distortions in the electrical grid. DC fast chargers further compounded these harmonic problems, even introducing voltage fluctuations. To rectify these issues and meet grid code compliance, solutions like harmonic filters and active power factor correction were essential. Effective management of these harmonics is not only critical for maintaining the stability of the customer’s EV charging station but also impacts the integrity of the surrounding electrical infrastructure.

Our Merus® Solution

To address the harmonic issues in our customer’s EV charging station, the recommended solution is the use of Merus® A2 Active Harmonic Filters. Suggested and installed by our local partner, Power Capacitors Ltd, the Merus® A2 offers an efficient way to improve power quality. These filters are specifically designed to manage the harmonics introduced by both AC and DC chargers, thereby enhancing the system’s overall performance and reliability.

Incorporating Merus® A2 into the electrical setup involves its strategic placement to effectively reduce harmonic distortions from the charging units. By actively isolating and filtering out specific harmonic frequencies, the Merus® A2 contributes to improved power quality, reduced voltage distortions, and a more stable electrical grid. The IP31 design of Merus® A2 ensured a seamless and straightforward installation, aligning well with the site’s indoor setting and existing infrastructure.

Segment / Application

EV-charging station for battery operated trucks

Location

United Kingdom

Power quality issue

- High current harmonic distortion

Merus® Solution

Merus® A2 – Active Harmonic Filter

Merus® A2 is a scalable, versatile, and durable active harmonic filtering solution designed and manufactured in Finland using innovative Merus® technology.

Customer Benefits

- Grid code compliance

- Reduced wear and tear on electrical components

- Reduced maintenance costs

- Longer lifetime of sensitive electrical equipment

- Improved system efficiency

- Optimized performance of the charging system

Results after installation

Since installing the Merus® A2 Active Harmonic Filters, our customer’s EV charging station has experienced significant improvements, including reduced wear on electrical components and extended equipment life. These improvements have resulted in a more efficient system that not only complies with demanding grid codes but also contributes to a more sustainable electric vehicle charging infrastructure. The expertise provided by our local partner, Power Capacitors Ltd., was invaluable in achieving these outcomes.

The Merus® A2 Filters have effectively minimized the harmonic distortions originating from AC and DC chargers. This optimization has led to increased energy efficiency and lower maintenance costs. Thanks to these advancements, the customer’s EV charging station now operates with improved power quality and grid stability, fulfilling industry standards for both performance and sustainability.

Case story: How AHF put a stop to packaging manufacturer’s production outages

Background

One of Canada’s largest manufacturers of innovative and sustainable packaging products was facing multiple transformer failures and production stops due to power quality issues at one of its many sites. The manufacturer needed to find a way to eliminate these recurring problems and troublesome interruptions. Multiple studies on power quality were performed by different contractors. Comsys Partner, ADM Engineering, was one of the companies performing power studies and providing analysis report.

Challenge

The challenge facing ADM was to determine what was causing the periodic failures in the main transformers and to recommend a reliable remedy. Following site measurements and subsequent analysis of the data captured by ADM and Comsys, the root of the problem was identified. The culprit was the resonance caused by the interaction between the natural resonant frequency of the power system, tuned capacitor banks, and nonlinear loads. Based on these findings, ADM was able to recommend ADF as the only viable solution to the site’s persisting problems.

Solution

ADF P300 – Active Harmonic Filters engineered and assembled by ADM using PPM300 modules.

Result

The ADF solution has been operating successfully since January 2020, eliminating resonance and harmonics as well as providing near unity power factor. Cost savings alone have amounted to around CAD 30,000 per month by eliminating harmonics and correcting the power factor. Increased uptime and productivity provide even more value.

Key Results:

- Mill power outage frequency significantly reduced

- Oil cooled transformer runs much cooler and requires less frequent oil changes

- Significantly reduced running temperature of several transformers

- Reduced nuisance trips and blown fuses of 600V switchgear

- Reduced saturation of feeding transformers, reduces voltage variations to nominal values

Current THD – before & after installing ADF

Power Factor – before & after installing ADF

Machine drives system supply voltages before active filters installation

Machine drives system supply voltages after active filters installation

Active + Passive = Hybrid

Active Harmonic Filters are becoming cheaper and very competitive compared to other active mitigation solutions such as Active Front End, which we explained here. In some applications that are not too dynamic, a passive harmonic filter makes perfect sense to reduce the investment. A combination of active and passive filters can be the best solution to reduce the investment cost while still being able to cope with dynamic loads. In such an application the passive harmonic filter focuses on the dominant harmonic component. This solution is currently used by for example the German auto industry in their production lines.

PQ Nosswitz, a German power quality solutions firm, devised a system to allow a flexible combination of active harmonic filters and passive harmonic filters to enable the most flexible and cost efficient solution for every project.

Active Harmonic Filters Increase Productivity in the Paper Industry

Active Harmonic Filter as a Tool to Save Money

Power quality mitigation products are not only used to fulfil regulations such as IEEE-519 and G5/4. They have actual effects saving both power and increasing productivity. This presentation by ABB exemplifies some of their early case studies indicating savings of up to 10%. Note that these savings compare to having no harmonic mitigation.

The cases below clearly show the great business value of implementing a high power quality standard within your facility. The secondary effects of complying with IEEE 519 or similar standards enables the local grid to be dimensioned for less reactive power and harmonic current thus saving money through thinner cabling, smaller transformers etc. Power quality mitigation is not only a cost in the general investment calculation but a tool to save money.

Harmonics – What They Are

What is Harmonics

Simply put: Harmonics are unwanted frequency components and unbalance in terms of uneven power distribution between the phases in the electrical network.

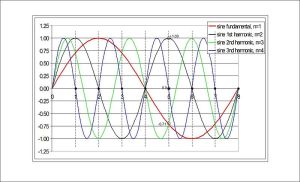

More exactly: Harmonics are disturbances to the sinusoidal voltage waveform. They are multiples of the supply frequency, in other words if the supply frequency is 50 Hz the fifth harmonic would be 250 Hz. These variations from the pure sine form are caused by non-linear loads from electrical machinery and appliances. These non-linear loads can be caused by anything from battery chargers to variable speed drives or flourescent lighting. High levels of harmonics can cause power quality problems and voltage distortions.

Harmonics and the power quality problems they cause can have expensive and often detrimental effects on machinery and appliances. Flourescent lighting may need to be changed continuously, electric motors may have a higher frequency of break downs and a shortened life span. Some common direct impacts of poor power quality in the shape of harmonics are:

- Lower production speed

- Increased energy consumption

- Charges for reactive power consumption

- Damaged equipment

- Premature equipment aging

- Data loss

The fact is that harmonics have become a problem for many business sectors and the costs are consistently rising. The number of disturbances are increasing and modern production equipment is becoming more sensitive to these disturbances.

Harmonic Distortion Standards

Harmonics caused by large machine parks can also have an effect the grid. This is why there has been an increase in regulations and standards required by municipals. Some examples of standards governing harmonics emissions are IEEE 519, G5/4, EN 61000, EN 50160, D-A-CH-CZ, among others. Some standards are also specific to certain applications, such as DNV or ABS for offshore applications. The standards most commonly require a voltage harmonic distortion below 5-8%.