Tagged: Active filter

ABB literature FACT CHECK

We came across ABBs brochure for the ACS880 Ultra Low Harmonic and Regen Drives which is ABBs Active Front End solutions. We noted that someone has been very imaginative on a level where it is necessary to point it out. Surprising for such a well renown market leader.

What are we talking about?

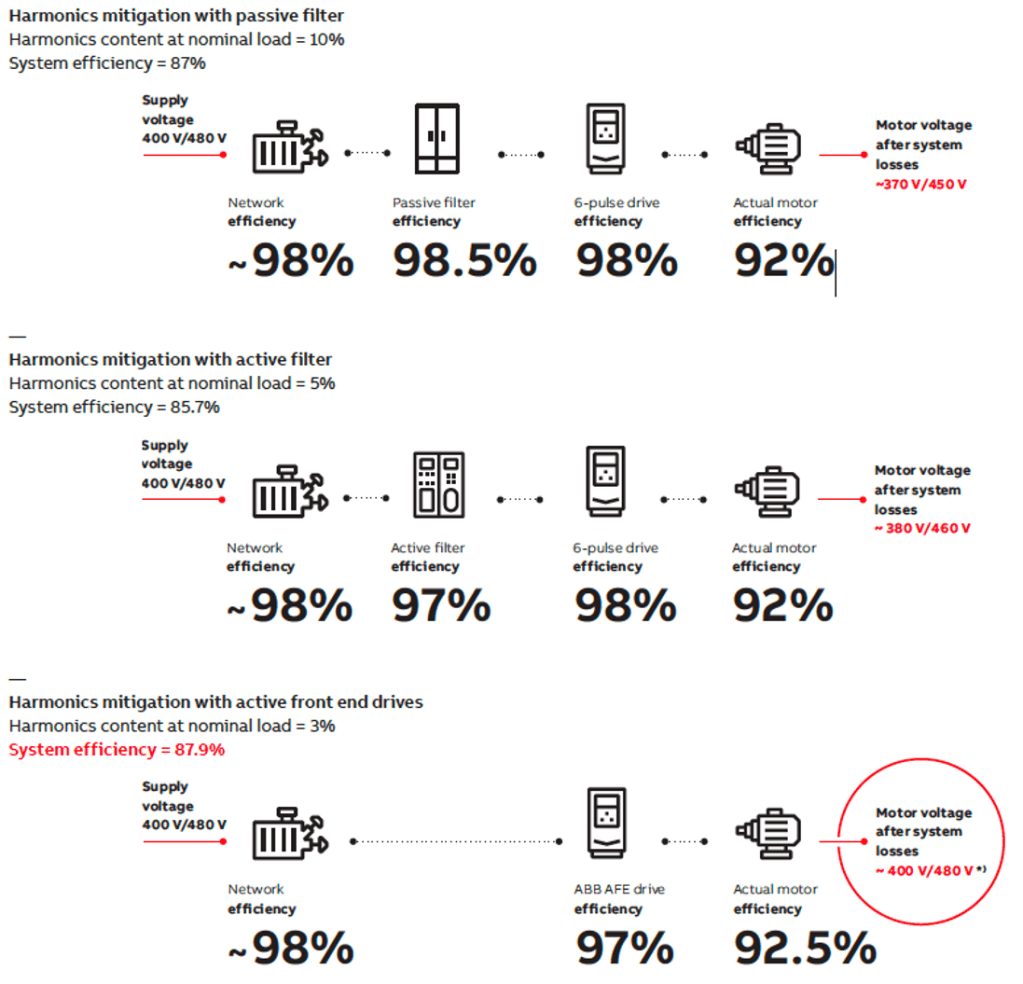

Below is a snapshot from ABBs brochure for the ACS880 highlighting the incredible advantage of using Active Front End(AFE) drives instead of using passive or active filters. The main point being that the AFE has a much higher system efficiency than Active Harmonic Filters(AHF) and Passive Harmonic Filters(PHF) while maintaining a very high THD-reduction.

Figure 1: Snapshot from ABBs brochure in question.

So what is wrong?

Well, lets start with the AFE efficiency of 97%. Sounds fantastic, as an AFE is 2 x inverter +1x LCL filter it sounds incredible. Which it is. Theoretical losses should be roughly 2×1,2+2% so maximum 96,6%. There is an easier way to verify this and that is to actually check ABBs own datasheet for the ACS880.

An 250 kW ACS880-UHD has 11 kW losses through heat. That is 4.4% or an efficiency of 95.6% far from the 97% stated. To be fair a wall mounted 110 kW AFE is rated at 3.5% losses indicating 96.5% efficiency but still well below 97%.

So AFE system efficiency is 95.6-96.5% at optimum.

Secondly they are making a big deal that a 6-pulse drive create a significant voltage drop which in turn reduce the motor efficiency. Based on the numbers this must be an AC-choke they are using. Most drives are outfitted with DC-chokes with significantly less voltage drop. It is correct that a passive serial filter cause a voltage drop. An Active Filter being placed in parallel does not cause a voltage drop.

So, once again lets go back to the ACS880 6p version which is equipped with a dc-choke as standard. A 250 kW 6 P ACS 880 has 1,7-2,4% losses (wall/cabinet). So 98% is a good average.

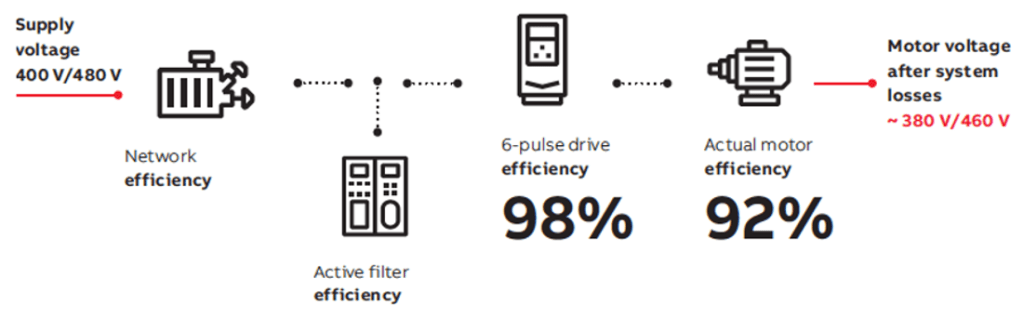

Thirdly, most blatantly to us Active Filter Aficionados they have placed the Active Filter in a serial configuration!? Thus assuming that the Active Filter is sized 100% to load just like the Front End. In reality a typical active filter is placed in parallel with the load and sized based on the THD-load or roughly 25-33% of the load.

Figure 2: We helped ABB marketing correct the system topology. AHF sizing only focus on THD-level.

Using a Comsys ADF P100 as reference of an modern Active Harmonic Filter, it has 97.4% efficiency or 2.6% losses according to their datasheet.

So the AHF system losses will be 0.25-0.33 * 2.6 = 0.65-0.86% or 99.14-99.35% for simplicity we use AHF system size to be 30% of load or 99.22% system efficiency.

Updated system efficiencies:

Active Filter

Network Active Filter 6-P Drive Motor System Efficiency

98% 99.22% 98% 92%* 87.6%

*) The voltage drop across a 6P drive should be somewhere <6 V + any reactor loss if installed thus much smaller motor loss difference than suggested here. We do not have good data however and leave it as it is.

ACS 880 AFE

Network AFE Drive Motor System Efficiency

98% 95.6-96.5% 92.5% 86.7-87.5%

Difference AHF vs AFE = 0.9 -0.1 %

Conclusion

So the Active Filter Configuration system efficiency is actually on par or slightly better than the ACS880 at full load.

That is without AHF sleep mode, modularity and other complimentary solutions available to Active Filters. At part load things get even worse for the AFE but that is a story for another post.

Enabling a seamless Champions League final in Istanbul with Active Harmonic Filter

Service Partner: Wömner Power Quality Solutions

Location:Istanbul, Turkey

Industry: Sports Venue

Timeline: 2020-2023

Background

When Istanbul was selected to host the 2020 Champions League Final, the Turkish Football Federation contracted Renaissance Construction to renovate the city’s Olympic Stadium as the venue. Although the final was delayed until June of 2023 due to the pandemic, the work proceeded as scheduled and Wömner Power Quality Solutions, Comsys’s partner in Istanbul, was selected to ensure that no power quality issues would disrupt the prestigious event.

Challenge

Predicting what could go wrong during the final is difficult for various reasons. Firstly, power is peak during games, which take place only two or three times a month at most. Secondly, the stadium is supplied from several medium voltage (MV) substations, each having two backup transformers making the measurement of energy consumption complex due to the uncertainty of not knowing which of the three transformers is being utilized. Thirdly, a total of 25 km of MV underground cable creates 180 kVAR of capacitive power per hour. During game time reactive power is balanced, but on no load condition capacitive power is there and because it is on MV level it cannot be easily measured due to the position of the meter, which is 6 km away. And finally, two large scoreboards with a lot of power electronic equipment were installed for the final, creating harmonics.

The customer’s main priority was on harmonics and trips due to these, as well as on reactive power management. Normally, other power quality issues are quite small.

Solution

A total of seven Comsys ADF P100N active harmonic filters were installed by Wömner; two at each of the three main substations for the stadium, and one additional unit at a smaller utility substation.

Result

Since the filters were installed in early 2020, the customer has experienced no problems due to capacitive penalties and game nights have been safe and secure. The Active Harmonic Filter technology is successfully compensating harmonics and preventing capacitive penalties.

Merus Power case study on EV-charging station

Segment background

The battery-operated truck industry has emerged as a transformative force within the transportation sector, offering a sustainable and eco-friendly solution to the longstanding challenges of heavy-duty vehicle emissions and fossil fuel dependency. These electric trucks, powered by advanced lithium-ion battery technology, are gaining momentum as an integral component of modern urban logistics and long-haul transportation. With the promise of zero-emission operation and significant reductions in operating costs over the long term, battery-operated trucks are not only aligned with environmental objectives but also represent a strategic choice for businesses aiming to optimize their fleet operations, comply with tightening emissions regulations, and contribute to a cleaner and more sustainable future for the global transportation industry.

Challenges at the customer’s facility

Driven by the need to comply with stringent grid code requirements, our customer recognized the necessity of improving power quality at their electric vehicle (EV) charging station. Specifically, they were facing challenges with harmonics, a common issue arising from the use of both AC and DC charging systems. The AC chargers, converting AC power to DC for the vehicles, were causing harmonic distortions in the electrical grid. DC fast chargers further compounded these harmonic problems, even introducing voltage fluctuations. To rectify these issues and meet grid code compliance, solutions like harmonic filters and active power factor correction were essential. Effective management of these harmonics is not only critical for maintaining the stability of the customer’s EV charging station but also impacts the integrity of the surrounding electrical infrastructure.

Our Merus® Solution

To address the harmonic issues in our customer’s EV charging station, the recommended solution is the use of Merus® A2 Active Harmonic Filters. Suggested and installed by our local partner, Power Capacitors Ltd, the Merus® A2 offers an efficient way to improve power quality. These filters are specifically designed to manage the harmonics introduced by both AC and DC chargers, thereby enhancing the system’s overall performance and reliability.

Incorporating Merus® A2 into the electrical setup involves its strategic placement to effectively reduce harmonic distortions from the charging units. By actively isolating and filtering out specific harmonic frequencies, the Merus® A2 contributes to improved power quality, reduced voltage distortions, and a more stable electrical grid. The IP31 design of Merus® A2 ensured a seamless and straightforward installation, aligning well with the site’s indoor setting and existing infrastructure.

Segment / Application

EV-charging station for battery operated trucks

Location

United Kingdom

Power quality issue

- High current harmonic distortion

Merus® Solution

Merus® A2 – Active Harmonic Filter

Merus® A2 is a scalable, versatile, and durable active harmonic filtering solution designed and manufactured in Finland using innovative Merus® technology.

Customer Benefits

- Grid code compliance

- Reduced wear and tear on electrical components

- Reduced maintenance costs

- Longer lifetime of sensitive electrical equipment

- Improved system efficiency

- Optimized performance of the charging system

Results after installation

Since installing the Merus® A2 Active Harmonic Filters, our customer’s EV charging station has experienced significant improvements, including reduced wear on electrical components and extended equipment life. These improvements have resulted in a more efficient system that not only complies with demanding grid codes but also contributes to a more sustainable electric vehicle charging infrastructure. The expertise provided by our local partner, Power Capacitors Ltd., was invaluable in achieving these outcomes.

The Merus® A2 Filters have effectively minimized the harmonic distortions originating from AC and DC chargers. This optimization has led to increased energy efficiency and lower maintenance costs. Thanks to these advancements, the customer’s EV charging station now operates with improved power quality and grid stability, fulfilling industry standards for both performance and sustainability.

Case story: How AHF put a stop to packaging manufacturer’s production outages

Background

One of Canada’s largest manufacturers of innovative and sustainable packaging products was facing multiple transformer failures and production stops due to power quality issues at one of its many sites. The manufacturer needed to find a way to eliminate these recurring problems and troublesome interruptions. Multiple studies on power quality were performed by different contractors. Comsys Partner, ADM Engineering, was one of the companies performing power studies and providing analysis report.

Challenge

The challenge facing ADM was to determine what was causing the periodic failures in the main transformers and to recommend a reliable remedy. Following site measurements and subsequent analysis of the data captured by ADM and Comsys, the root of the problem was identified. The culprit was the resonance caused by the interaction between the natural resonant frequency of the power system, tuned capacitor banks, and nonlinear loads. Based on these findings, ADM was able to recommend ADF as the only viable solution to the site’s persisting problems.

Solution

ADF P300 – Active Harmonic Filters engineered and assembled by ADM using PPM300 modules.

Result

The ADF solution has been operating successfully since January 2020, eliminating resonance and harmonics as well as providing near unity power factor. Cost savings alone have amounted to around CAD 30,000 per month by eliminating harmonics and correcting the power factor. Increased uptime and productivity provide even more value.

Key Results:

- Mill power outage frequency significantly reduced

- Oil cooled transformer runs much cooler and requires less frequent oil changes

- Significantly reduced running temperature of several transformers

- Reduced nuisance trips and blown fuses of 600V switchgear

- Reduced saturation of feeding transformers, reduces voltage variations to nominal values

Current THD – before & after installing ADF

Power Factor – before & after installing ADF

Machine drives system supply voltages before active filters installation

Machine drives system supply voltages after active filters installation

Active + Passive = Hybrid

Active Harmonic Filters are becoming cheaper and very competitive compared to other active mitigation solutions such as Active Front End, which we explained here. In some applications that are not too dynamic, a passive harmonic filter makes perfect sense to reduce the investment. A combination of active and passive filters can be the best solution to reduce the investment cost while still being able to cope with dynamic loads. In such an application the passive harmonic filter focuses on the dominant harmonic component. This solution is currently used by for example the German auto industry in their production lines.

PQ Nosswitz, a German power quality solutions firm, devised a system to allow a flexible combination of active harmonic filters and passive harmonic filters to enable the most flexible and cost efficient solution for every project.

Active Harmonic Filters Increase Productivity in the Paper Industry

Active Harmonic Filter Application in Ba Na Hills, Vietnam

Here is a great showcase of the effects of applying active harmonic filters on a cable car installation made by Power More in Vietnam. Ba Na Hills Mountain Resort are holders of three Guiness Records – Longest single rope cable car system, Longest distance between stations and Heaviest cable roll. For Ba Na Hills, power quality is a question of safety and service quality. With total harmonic distortion 5 times higher than the national regulated level, Ba Na Hills were facing several problems.

- Station to station communcation was interrupted

- Power factor penalties

- Damaged PFC capacitor units

- Inerference with PFC controller

- Reduced motor effeciency in generator mode to 50%

Applying ADF Power Tuning active filters from Comsys to battle both power factor correction and harmonic filtering resulted in:

- Eliminated risk of PFC failures

- Eliminated power factor penalties

- Increased motor efficiency to 100%

- Improved cable speed

Low Voltage Active Filter as a Medium Voltage STATCOM for Windpower

When the 32 MW Kville wind power station was being built in Sweden, the local grid owner Fortum was looking for alternatives for inductive compensation. The long underground cable length cause a dynamic capacitive reactive power problem that normally is compensated using a large MV inductor. The inductor is very large and costly device at these sizes and Fortum wished to investigate other alternatives.

Comsys used its extensive knowledge from MV applications in applying its liquid cooled low voltage Active Filter with a step up transformer to create a 2,5 MVA STATCOM solution to solve the problem. If applied correctly, an active technology is very compact and flexible enabling high availability. Comsys liquid cooled modular design offers a high degree of redundancy and availability as the modules can be operated individually.

A further complication was the requirement to measure at the PCC on the 130 kV level so the Low Voltage ADF STATCOM worked through two step-up transformers. After extensive simulations by Comsys, the system was designed and supplied through the turn key integrator Siemens.

The active filters where installed in an existing building and the step-up transformer was installed outside, saving valuable indoor space and requiring no additional transformer cooling.

The solution dynamically compensates the capacitive reactive power and keeps it in line with the utility’s requirement. Due to the STATCOM following the load dynamically and observing both voltage and current, optimal grid conditions are ensured during all operating conditions.

The investment cost was reported to be lower than using the customized inductor solution proving the competitiveness of small active STATCOM versus passive options.

The ADF P700 STATCOM is a perfect solution in a dynamic environment such as wind farms. It is as cost effective and compact as a passive solution but with superior performance.

AHF Compensates Thruster and Refrigeration Compressor

Danfoss used an Active Harmonic Filter to compensate the THD of their installed 960 kW of VFDs for thruster and refrigeration compressor on the fishing vessel Gitte Henning #8. The AHF ensured to keep the installation within class requirements. Read more at:

Active Harmonic Filters – Buyer’s Guide

Active Harmonic Filters are growing in popularity as a method to mitigate power quality issues. There are several factors to consider when specifying an active harmonic filter. Typical applications for active filters are compensation of variable frequency drives and data-centers to reduce the load on UPS systems or compensating the effects of renewable energy sources on the grid.

What is an Active Harmonic Filter and what is its Application.

The general definition to describe this application is an analog or digital device that measures the power quality on the grid side. It then injects current to compensate any unwanted deviations from the standard 50 or 60 Hz supply. Deviations can be mitigated in full or partially.

What Factors to Consider when Specifying an Active Harmonic Filter

Sensor or sensorless control

There are suppliers that provide sensorless control eliminating the need for current transformers. This solution reduce the installation cost. Sensorless is not used in all applications so make sure to check the application with the supplier. Sensorless control or voltage control as it is sometimes defined compensates the total THD. It is not possible to select a single source such as a single VFD. On the plus-side it is possible to protect a sensitive subgrid from a noisy primary grid.

Losses

Depending on design, the filter has higher or lower losses. Check the losses as this will reduce the Life Cycle Cost on your investment. Some active filters have up to 1%-point lower losses, which depending on your user profile, means a potential for considerable financial savings if calculated LCC over 5 years.

Harmonic Compensation Capacity

Harmonics are normally seen in the odd. Common capacity for active filters is 25th or 50th harmonic. Sometimes there is a claim of being able to mitigate the 51st harmonic, which has little value as harmonic order of 51 and above are normally not important.

Harmonics above the 50th are more difficult to measure as there are few PQ-meters that can handle such orders. There are however quite common sources such as Active Front End Drives that cause switching ripple above 3kHz, above the 60th harmonic (or above the 50th in 60 Hz systems).

There are a few Active Harmonic Filters capable of compensating such frequencies. Choose a filter according to the needs specified by your measurements.

A filter’s capacity to compensate a certain harmonic order is only part of the story. Another important factor is de-rating, discussed below.

Response time

Some power quality phenomena occur extremely fast requiring the mitigation to be even faster. If your process is affected by fast flicker or transients, take special care to evaluate the response capacity of the filter. Flicker is a specific phenomena that normally requires special software to compensate flicker in a controlled environment.

Interharmonics

Interharmonics is commonly caused by syncronisation issues. If your installation includes such interharmonic sources, the type of active filter changes and the vendor has to be consulted. This is a common issue on some types of older wind turbines.

EMC

In Europe there are strict guidelines regarding EMC. If you want to be sure that the active filter does not interfere, the filter must be fitted with a properly tuned EMC-filter.

De-rating

An Active Harmonic Filter’s rating is normally defined at nominal load, meaning at 50/60Hz. As the filter works further up the harmonics its capacity compared to nominal starts to de-rate. The de-rating curve is documented by all serious suppliers and should be available if you ask them.

A de-rating of 50%, at say the 13th harmonic, means that a 100A filter only has the capacity to compensate 50A at the 13th. Naturally if you have harmonics of higher order it becomes more important to check the de-rating.

De-rating is a matter of how robustly the filter is designed. Some suppliers offer zero de-rating up to the 7th before capacity starts to fall.

Physical Footprint – How Much Cabinet Space is Required?

Most active filter suppliers offer several alternatives regarding installation. Wall mount, Cabinet and IP00 modules to install in cabinets. Efficient use of cabinet space translates to lower system cost. Some filters have a modular design and can be enhanced with further capacity without adding to the footprint.

Modularity

As mentioned, a modular design of your Active Harmonic Filter enables you to adapt the filter to potential changes in your future power compensation needs. The modular design means that you can easily add to the filter’s capacity within the existing cabinet, saving both cost and space.

Commissioning Software

Does the filter have built in commissioning software? Commissioning and service of Active Filters can be quite time consuming. Ask for a review of the support software included in the machine. Some suppliers have an extra charge for the necessary software. Minimum required functionality should be that the system performs a self-check of Voltage and CT phase order, CT polarity check, self-diagnosis, and self-calibration. Such features will quickly find installation errors before they can cause problems and will also shorten the needed commissioning time.

If the filter does not have this type of support software the commissioning becomes much more complex and might even require external support adding to the system cost.

HMI

There are different HMI setups. Some have a very simple front HMI while others include graphs showing the current and voltage waveforms and many further functions. A great added value is to have at least a web-based interface allowing in-depth monitoring and control functionality. Then no extra PQ-meter is necessary.

Smart Grid Functionality

Active filters have a built in rudimentary power and power quality meter to calculate the required compensation. Some filter manufacturers make use of this fact and enable the user to connect all filters on site and company wide through a web based architecture. An operator can then have an overview of the status of all connected cabinets and log them. This enables the possibility to log events that could or should have caused production disturbances, status monitoring of individual filters as well as remote control capability. Email and text alerts to dedicated service personnel from the filter reduce response time dramatically.

IP/NEMA Class and Water Cooling

Water-cooled Active Filters enable very good cooling of the IGBTs, the most critical component in the Active Filter. Water-cooling reduces overheating immensely, which increases availability in the same way as for Variable Frequency Drives. The power density of the installation is also improved.

Voltage

Active Harmonic Filters are offered in a range of voltages. Most common ranges are 380–415V, up to 480 V. Higher voltages up to 600 and 690V are also available without step-up transformer, reducing foot print. Some suppliers have the capacity to supply MV ratings as well, normally using a step-up transformer. The active filter can then act as STATCOM.

Battery add-on

In recent years several suppliers are offering battery connectivity to create a battery energy storage system for FCR and peak shaving. The active filters on-load capabilities are perfect for grid connectivity applications.

Sensorless Voltage Control

Recently a new type of sensorless solution make it much easier to install as no CTs are required which is standard for active harmonic filters. This method can not control specific frequencies but can be used to even mitigate noise from the grid.

Resonance Damping

Some filters offer resonance damping making them ideal in highly complex situations.

Multimaster

When building large systems with several filters acting together they are normally controlled by a master filter. In these cases some suppliers provide a multimaster option. In case the master-filter fail, another filter take up the master role and the system as a whole can continue filtering.